Putting Quality into Operation

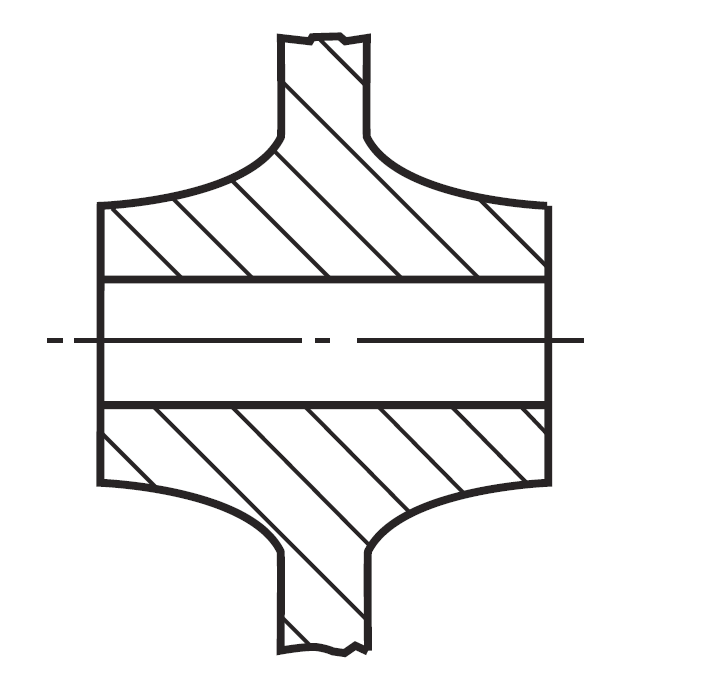

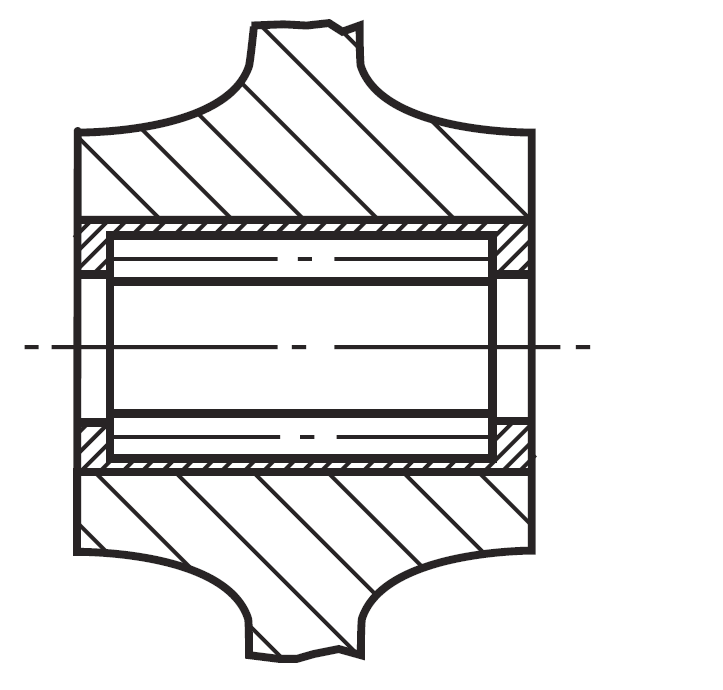

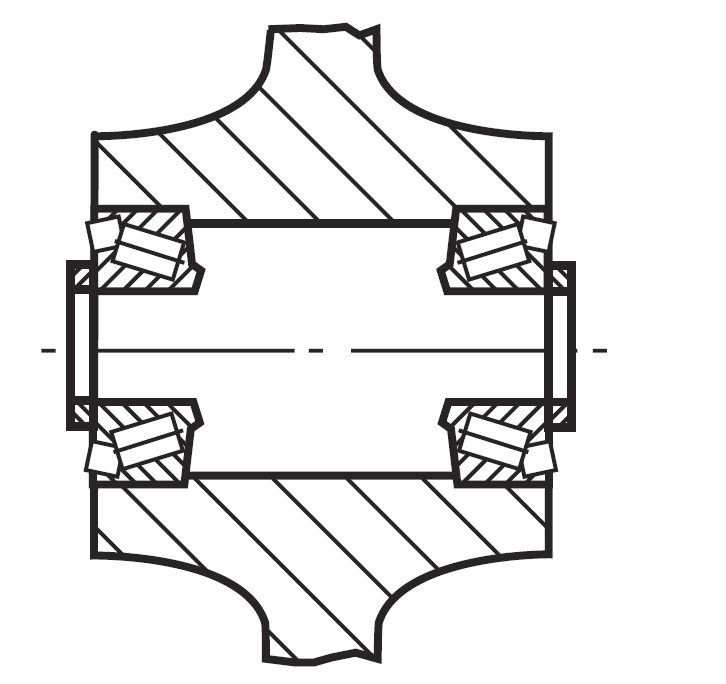

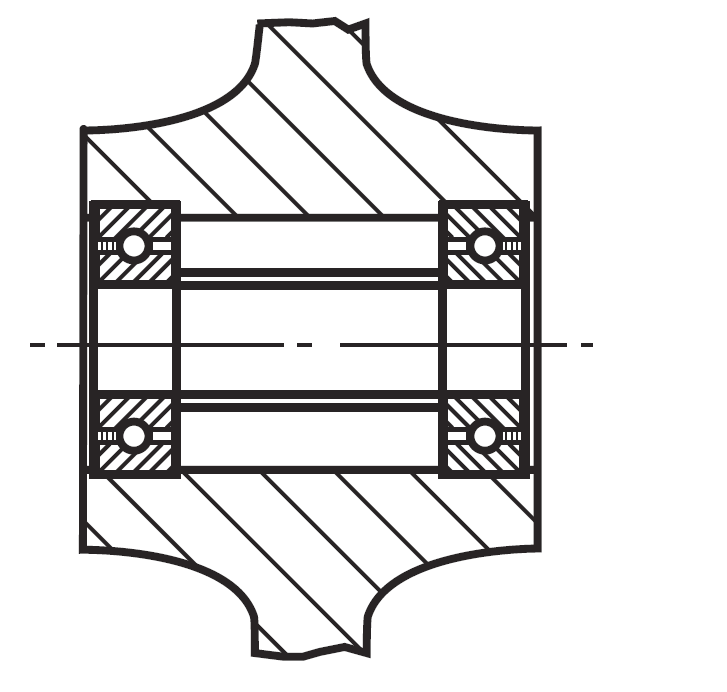

The type of construction of the wheel bearing is of great significance for the operating properties of a castor and therefore for the mobility of the equipment. Wheel bearings must meet the most varied requirements, such as load bearing capacity, duration of use, environmental influences, resistance to impact shock, resistance to rolling, and resistance to weather, etc. We distinguish between the following wheel bearings: