For Going in the Right Direction

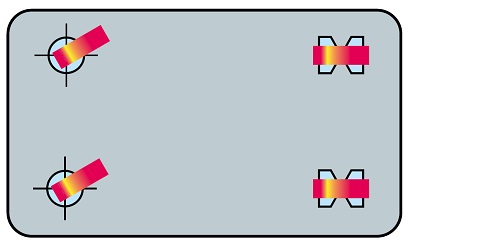

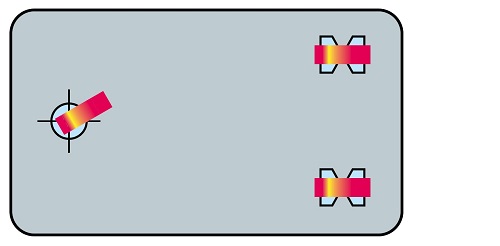

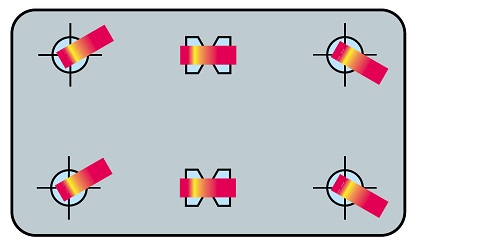

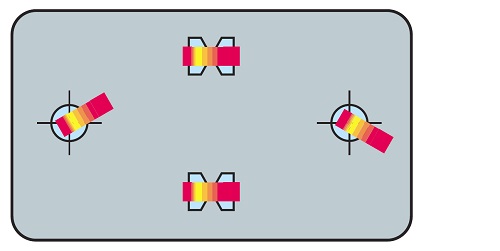

The steerability of equipment and machines is dependent upon the position of the individual castors on the equipment. Various arrangement possibilities show what direction it can go.

In this section, you can find the various definitions and uses of castor types. This then leads onto the castor combinations - which explains various combinations which can be applied to applications.